Thermal Paper Innovations: Enhancing Print Quality and Durability

The Role of Thermal Paper Innovations in Modern Industry

Demand for High-Performance Receipt and Label Solutions

Businesses across many industries have started relying heavily on thermal paper for things like receipts, shipping labels, and event tickets because it prints so fast and works reliably. With retail chains growing bigger and logistics operations getting more complex day by day, companies need better quality thermal paper than ever before. Manufacturers are responding by developing new coatings and materials that make the paper last longer and work better under tough conditions. Real world experience shows that switching to premium thermal solutions saves money in several ways. Fewer misprints mean less waste, and since there's no need for ink cartridges or toner refills, maintenance becomes much simpler over time. Some warehouses report cutting their printing costs almost in half after making the switch to thermal technology.

Balancing Print Quality with Environmental Concerns

We're seeing a big move towards greener options for thermal paper these days as people become more aware of environmental issues. The old school thermal papers typically had stuff like BPA in them, and that's been causing all sorts of worries about what happens to our health and the environment over time. Because of this, manufacturers are starting to look at different materials that won't harm anyone while still working well. Companies that switch to these eco options tend to see some real benefits too. Their customers notice and appreciate the effort, which helps build trust and keeps folks coming back. More and more businesses realize going green isn't just good for the planet, it actually makes business sense too. When shoppers know a company cares about sustainability, they're more likely to support it, creating better relationships that last through tough times.

Breakthroughs in Thermal Paper Chemical Formulations

BPA-Free Developers: Pergafast⢠and Eco-Friendly Alternatives

Thermal paper tech has taken a big step forward with products like Pergafast⢠entering the market. These BPA-free formulations tackle two major issues at once: print quality problems and those pesky health worries we've all heard about. Traditional thermal papers used to contain Bisphenol A, a substance linked to various health risks and environmental damage. Now companies are turning to alternatives like Pergafast, which actually works better than what came before. Tests show these new papers deliver the same sharp prints while keeping workers and customers safer. Looking at data from EPA reports makes it clear why switching matters so much. The numbers tell us that moving away from BPA isn't just good practice, it's becoming essential for protecting public health in our workplaces and communities.

Hybrid Bonding Technologies for Durable Imaging

New advances in hybrid bonding tech have taken thermal paper materials to another level when it comes to how tough they are against wear and tear. What these bonding methods do is actually improve how well the ink sticks to the paper surface, resulting in sharper images that don't fade so quickly either. With better bonding technology, printed text stays clear and easy to read even when exposed to harsh conditions. We've seen this work out in practice too. Thermal papers treated with these improved bonding techniques hold up much better against things like getting wet or scratched, something that matters a lot in industries where documents need to last. Think about warehouses tracking shipments or hospitals keeping patient records. These places really depend on paperwork that won't smudge or rub off after handling.

Moisture-Resistant Coatings for Extended Shelf Life

New developments in moisture resistant coatings have made a big difference in how long thermal paper lasts before it deteriorates. Tests show these special coatings cut down on spoilage problems when the paper sits around in normal environments, which means they're changing things for companies needing durable paper products. Stores report better customer reactions when their receipts or labels come with this kind of protection, showing people actually notice and appreciate the improvement. Retailers, pharmacies, and even those complex supply chain operations all benefit from thermal papers that stay readable longer without getting ruined by humidity or dampness.

Advancements in Thermal Paper Structural Design

Pre-Coat Layers for Heat Insulation and Smoothness

The pre-coat layers really make a difference when it comes to thermal paper's ability to insulate against heat and maintain a smooth surface, both of which are pretty important for getting good print quality. They actually cut down on those frustrating paper jams we all know too well and can boost how clear the printed text appears. Looking at what experts have found, thermal papers with proper pre-coating tend to run into problems less often during printing sessions. This means printers work better overall and spend less time sitting idle waiting for fixes. Real world tests in busy printing environments back this up too. These coated papers keep producing top notch results even under pressure, which explains why so many businesses in sectors where precise printing matters most have started making the switch to them recently.

Top Coat Innovations for Fade Resistance

New developments in top coat tech are making a big difference when it comes to how long printed images last on thermal paper before they start fading away. The latest coatings actually help prints hold up much better in everyday situations where they get exposed to various elements. Think about those signs outside stores or restaurant receipts that need to stay legible despite sun exposure, moisture, or just general handling over time. Customers who've used this stuff report that their brand messaging stays clear and professional looking for longer periods, which matters a lot for businesses trying to maintain consistent visual identity. Beyond keeping things looking fresh, these improvements give people more trust in thermal paper products overall, knowing they won't deteriorate quickly after being printed.

Core Material Optimization for Printer Compatibility

Getting the right core materials sorted out is pretty much a must these days if we want better compatibility across different thermal printers and actually improve how users feel about their experience. When manufacturers get this right, thermal papers just work better with printers overall, which means less jamming and fewer headaches for people trying to print receipts or labels. Industry data shows printers run about 15% faster on average when using properly optimized materials. Many businesses notice this difference too, with shop owners reporting they spend less time fixing paper problems and more time running their actual businesses. At the end of the day, better core material design translates into real world benefits for anyone working with thermal printing systems day in and day out.

Product Showcase: Cutting-Edge Thermal Paper Solutions

Thermal Paper Permanent Hotmelt Adhesive Blue Glassine

The Thermal Paper Permanent Hotmelt Adhesive Blue Glassine has become quite popular across different industries thanks to how well it works in so many situations. What makes this adhesive special is its ability to stick firmly on almost any surface regardless of temperature changes, which explains why it's commonly used for both food packaging and medical label applications. When it comes to cutting through materials and peeling off without leaving residue, this product really shines even when faced with tough conditions during production processes. Many professionals who work with this adhesive point out that its moderate initial stickiness actually helps a lot when applying labels to tiny bottles or other fragile items where too much grab would be problematic.

TDS Thermal Paper 3F Removable Glue for Logistics

TDS Thermal Paper 3F comes with this cool removable glue feature that's become pretty much essential in logistics work these days. Retailers love using it for price tags on shelves and those big discount stickers for furniture displays because they can move them around without leaving residue. The sticky stuff works well across different conditions too, though warehouse managers need to watch out for extreme heat situations and definitely steer clear of PVC surfaces where it just won't stick properly. Most facilities find this balance between stickiness and removability makes their labeling operations run smoother while saving money long term.

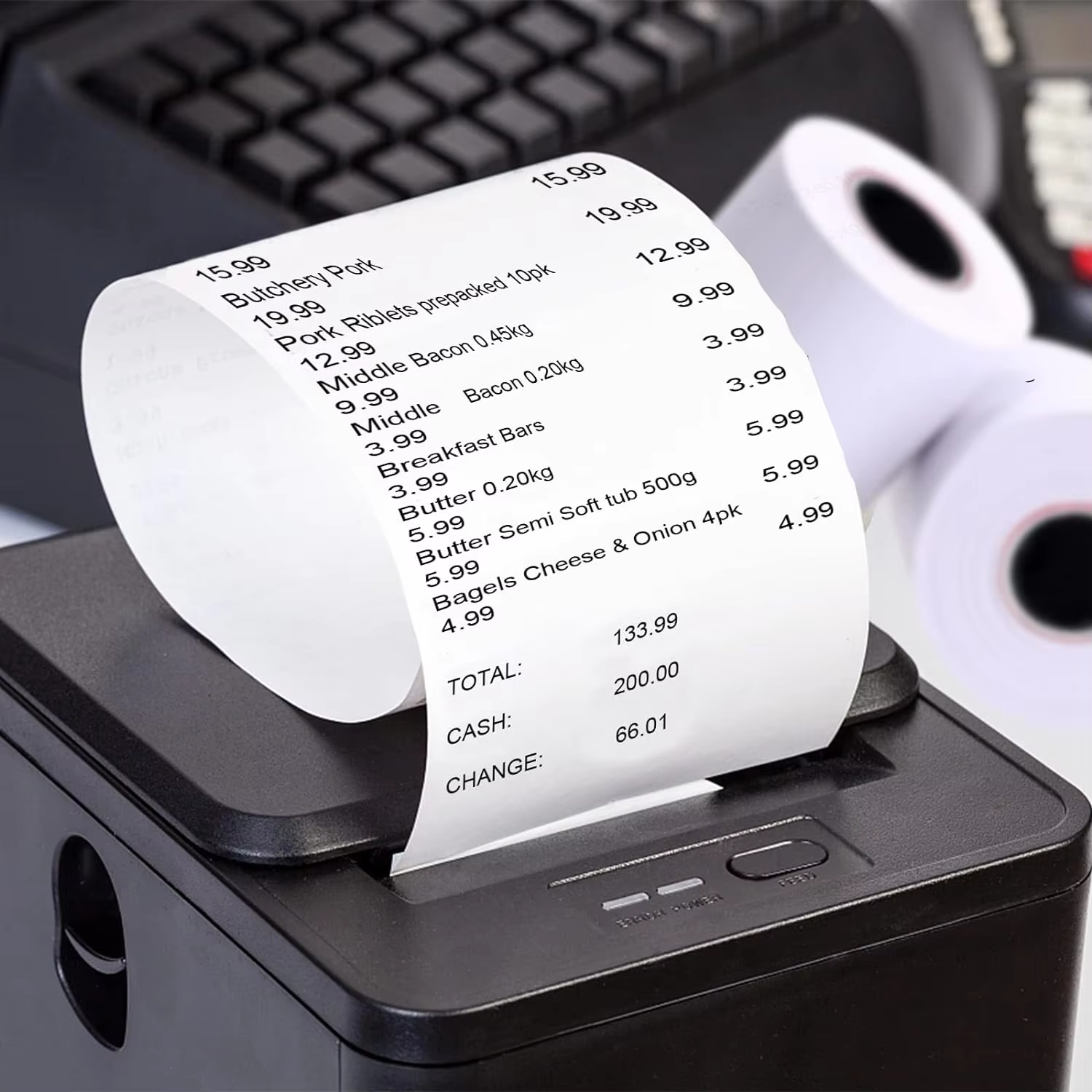

Factory-Direct ATM/POS Thermal Receipt Rolls

Getting thermal receipt rolls straight from manufacturers gives businesses peace of mind about quality while cutting costs for ATMs and point-of-sale systems. Most of these rolls come from pure wood pulp, which makes them both customizable and comes in different sizes so they fit whatever equipment needs them. Companies that have switched to buying directly report fewer issues with inconsistent print quality or unexpected price jumps. For small businesses especially, this direct approach can make a big difference in monthly expenses without sacrificing reliability. The savings stack up over time as inventory management becomes simpler when dealing with one consistent supplier instead of multiple distributors.

Customizable Waterproof Thermal Paper Without Liner

Waterproof thermal paper that can be customized without needing a liner was developed specifically for applications where moisture resistance matters most. This type of paper works really well when labels need to stick temporarily but come off later, which makes it great for things like scales used in stores or those little tags printed by barcode machines. Industry professionals often mention two main selling points: first, how easy it is to tailor this material for different needs, and second, its ability to perform across various conditions. However there's one catch worth noting nobody likes talking about but important nonetheless if we want clear images over time. The paper doesn't handle long periods of high temperatures or dampness very well so storage conditions matter quite a bit for maintaining print quality.

High-Speed Die-Cutting Thermal Labels for Retail

The introduction of high speed die cut thermal labels has really changed how efficiently retailers operate, making things go faster at checkout and keeping customers happier overall. The manufacturers have made some smart improvements to these labels so they work better for what stores need day to day. They stick much better now thanks to improved adhesives which makes applying them quicker and easier for staff. Retailers who switched to these new labels notice big differences in how smoothly operations run. Customer service gets better because lines move faster, while employees spend less time dealing with label issues. These changes aren't just minor tweaks either they represent real progress in store operations across the entire retail sector.

By showcasing these innovative products, companies can stay at the forefront of thermal paper solutions, meeting diverse demands across industriesâfrom logistical labels to retail efficiency boosters.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

ID

ID

SR

SR

SK

SK

SL

SL

SQ

SQ

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

MK

MK

UR

UR

BN

BN

LA

LA